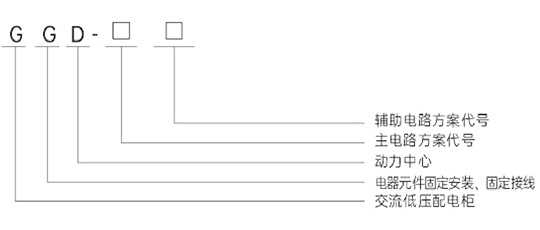

GGD low voltage fixed switchgear is applicable to the power conversion of power distribution equipment with AC 50Hz, rated working voltage of 380V and rated working current of 5000A in power plants, substations, factories and mining enterprises. It is used for power conversion, distribution and control of power, lighting and distribution equipment. GGD AC low-voltage distribution cabinet is a new low-voltage distribution cabinet designed according to the requirements of power users and design departments and based on the principles of safety, economy, rationality and reliability. The product has the characteristics of high breaking capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, strong seriality and practicability, novel structure and high protection grade.

GGD cabinet body adopts the form of combined cabinet. The frame is locally welded and assembled with standard cold-formed steel or directly assembled. The two sides of its profile are provided with installation holes with fixed modulus, which makes the frame assembly flexible and convenient.

According to the requirements of modern industrial product modeling design, GGD cabinet adopts the method of golden section ratio to design the cabinet shape and the division size of each part, so as to make the whole cabinet beautiful and fresh.

There are different numbers of cooling holes at the upper and lower ends of the cabinet. When the electrical components in the cabinet are heated, the heat rises and is discharged through the upper slot holes, while the cold air is continuously supplemented and rejected by the upper and lower slot holes, so that the sealed cabinet forms a natural ventilation channel from bottom to top to achieve the purpose of heat dissipation.

The cabinet door is connected to the frame with a rotating shaft movable dumpling chain, which is convenient for installation and disassembly. A mountain shaped couch plastic strip is embedded at the folding edge of the door. When closing the door, the strip between the door and the frame has a certain compression stroke, which can prevent the direct collision between the door and the cabinet and improve the protection grade of the door.

The top cover of the cabinet can be removed when necessary to facilitate the assembly and adjustment of the main bus on site. Lifting rings are installed at the four corners of the cabinet top for lifting and shipping. The protection grade of the cabinet is ip3d, and the user can also choose between ip20-ip40 according to the requirements of the service environment.

A section of outgoing copper bar is led out from the outgoing terminal of the low-voltage circuit breaker for feeding, and the three phases are staggered and fixed on the insulated mounting beam. The advantages of this configuration are:

It is convenient for cable installation. Due to the limited space of wiring terminals on the low-voltage circuit breaker, it is impossible to install cables with large diameter. Through the outgoing copper bar, it is convenient to connect without space restriction.

The staggered outgoing copper bars increase the electrical insulation distance and facilitate installation and maintenance.

By installing the cable through the outgoing copper bar, the force generated by the cable can be decomposed to the installation beam; Effectively prevent the potential safety hazards such as bolt looseness and heating caused by stress or electrodynamic vibration of the circuit breaker, and even short-circuit fault.